How ZWHAND Redefines Robotic Degrees of Freedom and Drive Technology

As robotics technology advances rapidly, the dexterous hand—serving as the key end-effector for humanoid robots to interact with the physical world—directly determines whether robots can perform fine and complex operations. Building on more than 20 years of expertise in micro-drive technology, ZWHAND has introduced a fully direct-drive dexterous hand with 17–20 degrees of freedom. This achievement not only marks a breakthrough in dexterity but also pioneers a new paradigm in drive technology, setting an industry benchmark.

Breakthrough in Degrees of Freedom: From Bionics to Beyond

With 17 active degrees of freedom (expandable to 20), ZWHAND offers far greater flexibility than the industry average (typically 12 DOF) and approaches the 27 DOF of the human hand. This design enables the hand to perform highly intricate tasks such as threading a needle or precision assembly, demonstrating significant potential in surgical robotics, industrial automation, and beyond. By comparison, Tesla Optimus dexterous hand has 16 DOF and AgiBot robot has 12 DOF, giving ZWHAND’s solution a clear advantage in precision operations.

The increase in degrees of freedom is not merely about adding more joints, but rather about an optimized layout inspired by bionics. ZWHAND adopts a single-joint drive design, with each finger joint equipped with an independent drive unit to ensure precise and coordinated motion control. The opposability of the thumb, independently driven joints, and multi-DOF wrist coordination together form a highly biomimetic operating system that adapts to grasp objects of varying shapes and materials.

Fully Direct-Drive Architecture

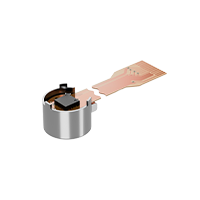

Traditional dexterous hands often rely on tendon or gear drives, which suffer from high energy losses (efficiency only 65%–75%) and long response delays (≥25 ms). ZWHAND’s innovation lies in embedding miniature stepper motors or coreless motors directly into the finger joints, paired with ball-screw actuators for linear motion. This approach eliminates transmission losses, raising efficiency to ≥95%.

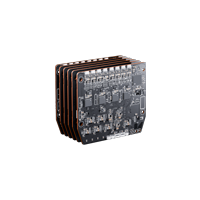

The core of this design lies in micro-integration: the motor, gearbox, and screw drive unit are highly integrated, shortening the transmission chain to 35 mm. This allows response times as short as 8 ms and force resolution of up to 0.05 N—equivalent to the force needed to pinch a sheet of A4 paper. Additionally, the high power density of coreless motors (>0.5 kW/kg), combined with the mechanical advantage of the screw, enables a single finger to generate 10–20 N of gripping force while reducing overall weight by more than 30%.

Achieving this breakthrough design was not without challenges. Micro-integration raised issues of heat dissipation and load balancing. ZWHAND solved these with an innovative cooling solution combining ceramic bearings and thermally conductive housings, along with a bidirectional thrust structure to ensure axial balance. This design enables stable operation under high-frequency usage. Furthermore, automotive-grade manufacturing standards and 100,000-cycle fatigue testing validate a design lifespan of over 10 years—far exceeding the 500,000-cycle limit of tendon-driven hands.

ZWHAND has not stopped at mechanical breakthroughs. Its next-generation R&D is already targeting higher levels of intelligence. In collaboration with the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, the “Joint Laboratory for Intelligent Dexterous Hand Systems” is focusing on AI cerebellum-inspired control algorithms and tactile sensing with electronic skin. In the future, the dexterous hand will gain autonomous learning capabilities, dynamically adapting grasping strategies to different objects, further expanding applications in service robotics, medical assistance, and more.